3D Printing Issues – 5 Reasons Your 3D Prints Keep Failing And How to Fix Them

3D Printing Issues are a pain, nothing stings more than checking your printer hours into a print, only to find a spaghetti mess of filament instead of the crisp object you imagined. So let’s dive right into some clear, simple reasons your 3D prints could be failing and exactly how you can fix simple 3D Printing issues that every faces..

1. Poor Bed Adhesion

If your prints just won’t stick to the printing surface, expect shifting or even K.O.s halfway through your print.

Quick Fixes:

- Clean Your Surface: Oil and dirt create a slippery surface. Wipe your build plate routinely with Isopropyl alcohol (IPA).

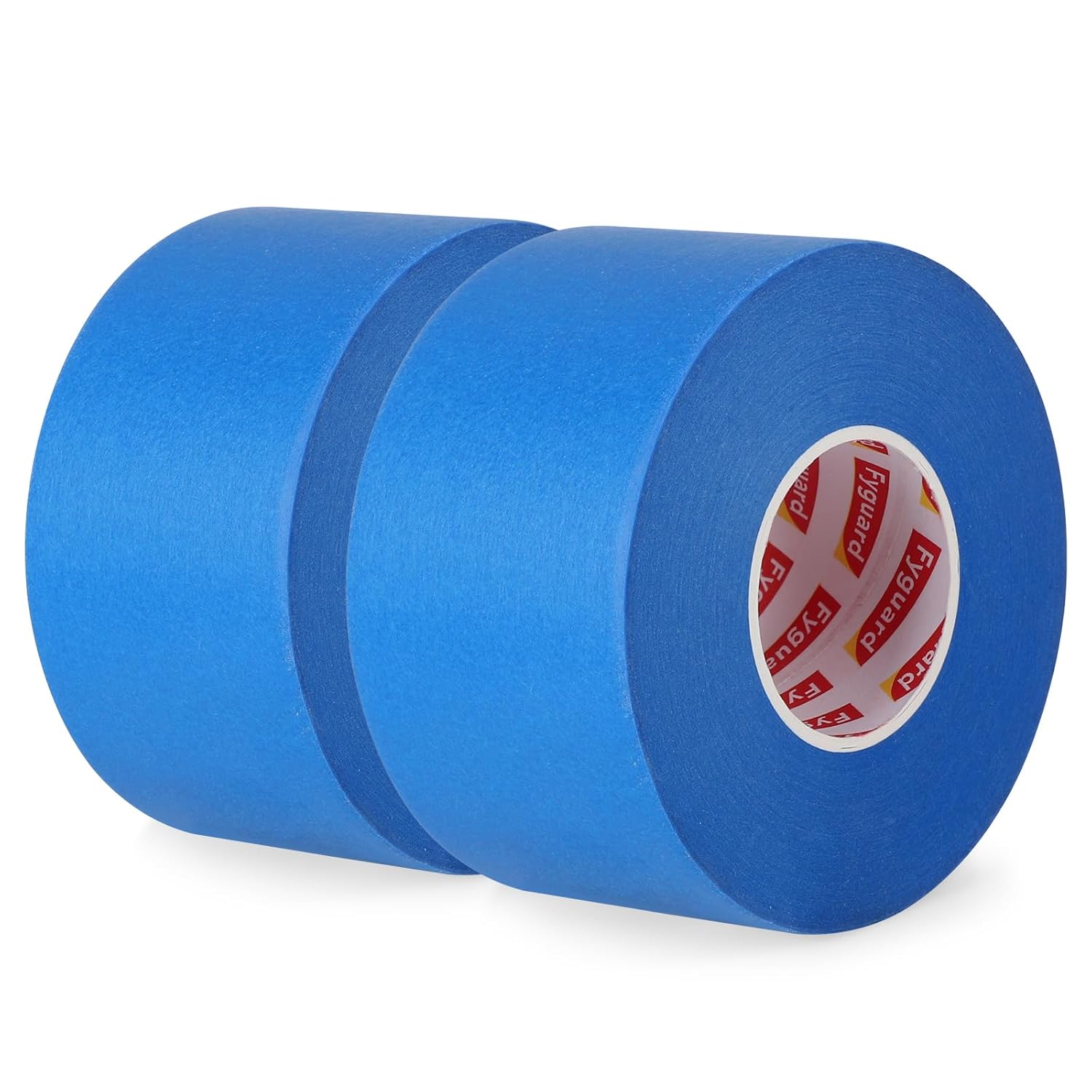

- Better Adhesion Materials: Try using blue painter’s tape, glue sticks, or a special adhesive like Magigoo. PEI Plates may also help out, especially magnetic ones.

- Check the Bed Level: A poorly leveled bed can be a headache, ensure your nozzle is properly positioned close to the bed.

The package contains 2 rolls of blue masking tape, each roll is 55yd/50m long and 1.89inch/48mm wide. Painter’s tape is small, easy to transport and suitable for daily and industrial use. (Tip: The inner diameter of the tape is too small to fit in a conventional dispenser.)

2. Incorrect Print Temperature

Temperature is crucial. Too hot, and you risk blobbing and stringing. Too cold, layer adhesion weakens and prints become brittle.

Quick Fixes:

- Follow recommended temperatures on your filament labels.

- If stringing is happening, try lowering your nozzle’s temperature by 5-10°C increments.

- Print a temperature tower calibration test, it greatly helps in picking optimal settings.

3. Improper Retraction Settings

Stringing and blobbing often come from poor retraction settings. If your prints have unsightly strings like a Halloween decoration, retraction could be the main culprit.

Quick Fixes:

- Enable and fine-tune retraction in your slicing software. Typical starting points are 5-7 mm for Bowden extruders, and 0.5-2 mm for direct drive extruders.

- Make slight adjustments in increments until the strings vanish.

- Consider increasing retraction speed slightly for cleaner results.

4. Wrong Print Speed

Sure, we all love speed, but crank it up too high and your quality takes a nosedive—especially with detailed and precise prints.

Quick Fixes:

- Slow down. Quality printing usually sits comfortably between 40-60 mm/s.

- Implement some speed tests and calibration prints to find your machine’s sweet spot.

- Use speed variations: keep walls/visible surfaces slow, but crank up infill speeds where quality matters less.

5. Poor Filament Quality or Moisture Absorption

Filament degrades over time, especially when stored improperly. Moisture, dust, and poor material purity can sabotage your efforts.

Quick Fixes:

- Store your filaments in airtight boxes with silica gel packets to fend off humidity.

- Dry your filaments using established drying methods or filament dryers (about 45-50°C for PLA).

- Invest in high-quality filament brands known for consistency and controlled moisture levels.

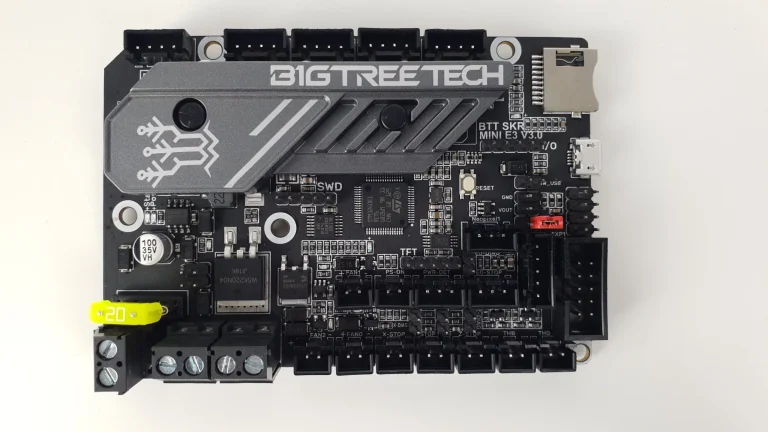

By addressing these five fundamental reasons early on, you’ll drastically cut down on print fails and frustration. Remember, every printer has its own quirks, so don’t be afraid to experiment, calibrate, and document your tweaks for better and better results over time. Once you get the hang of 3D printing, find out how you can turn your 3D printer into a gold mine, make your 3D printer faster, or flash Klipper!

Happy printing!